You see negative reviews about rough edges or poor finishes on your products. It hurts your brand image and sales numbers immediately. The real problem often hides deep inside the injection molding process1 used by your factory.

High-quality injection molding requires premium materials2, precise mold design optimization3, and strict quality control systems4. Focusing on details like parting lines5 and gate locations6 ensures a smooth, premium finish that reduces defects and creates a safe, comfortable user experience for your customers.

Many buyers overlook these technical details because they trust the factory completely. I will show you why understanding these specific molding elements is the key to your success.

Does the Material You Choose Determine the Life of the Product?

You worry about safety complaints and products that break too easily. Cheap plastic feels bad to the touch and smells chemical. This scares away your loyal customers.

Material selection is the foundation of product quality. Using international standard materials like food-grade Silicone7, ABS, and TPE ensures safety, durability, and compliance with regulations like REACH and RoHS8, protecting your brand from legal risks.

I believe that the soul of a product starts with the raw material. In the adult toy industry9, the material must be safe for the body. We cannot use recycled plastics that contain harmful substances. At YCSLife, we see many factories trying to save money by using "leftover" materials10. This is a huge mistake.

You need to know the specific characteristics of the materials you order. For example, silicone must be soft and skin-friendly, while ABS plastic needs to be strong and rigid. We strictly follow RoHS and REACH standards. Every batch of material we receive goes through a strict inspection. This includes ABS plastic parts, TPE, Silicone, and even the motors and batteries.

Here is a breakdown of why material selection11 is critical for your brand:

| Material Type | Common Usage | Key Benefit | Our Standard |

|---|---|---|---|

| Silicone | Body contact areas | Hypoallergenic & Soft | Food-grade, Smooth touch |

| ABS | Vibrator bodies/Controllers | Impact Resistance | High strength, Eco-friendly |

| TPE/TPR | Strokers/Sleeves | Flexible & Realistic | Phthalate-free, Safe |

| PC | Transparent parts | Heat Resistance | Clear, Durable |

If the material is bad, the best design in the world cannot save it. We use materials that pass international certifications. This ensures that your product feels expensive the moment the customer opens the box.

Can Minor Design Tweaks Save You Thousands of Dollars?

You face delays because the final product looks ugly or has sharp lines. Molds need constant fixing, which costs you time and money. This creates stress before your product launch.

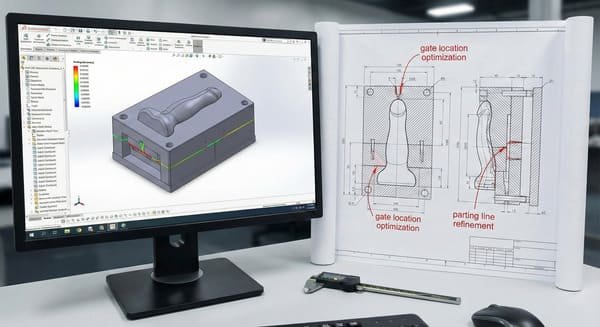

Optimizing mold design before production prevents costly aesthetic defects. Addressing specific details like parting lines5 (mold lines) and injection gates ensures the product looks seamless and functions perfectly without requiring expensive rework later.

Many brand managers focus on the shape but ignore the mold engineering. This is where my experience comes in. I want to share a story about a client named Antonio. He is from Europe and has very high standards. Before he came to us, he tried to make a new product in Zhejiang. He opened two different sets of molds there. Both failed.

The problem was the "parting line"—the line where the two halves of the mold meet. On his product, this line was very visible and rough. It made the toy look cheap. The factory in Zhejiang said it was impossible to hide. Antonio was frustrated and ready to give up.

When he came to me, I looked at the design. I used my experience to find a solution. I suggested that we make a 0.5cm high-gloss treatment on the edge of the mold. This small change made the parting line disappear into the design. It looked intentional and beautiful. Antonio was shocked. We solved in one week what others could not solve in months. Now, we are his only supplier.

Design optimization also includes the "gate location." This is where the plastic enters the mold. If you put it in the wrong place, it leaves a mark on the main surface. We analyze the mold flow carefully. We hide these marks in areas the user does not see. We have a strong R&D team that can go from design to production in 60 days because we anticipate these problems early.

How Does Precision Manufacturing Affect the User Experience?

Noisy motors and loose parts ruin the mood for your customers. Buyers want quality they can feel and hear. A rattling product gets returned immediately.

Precision manufacturing utilizes automated injection molding and dust-free assembly to maintain tolerances within ±0.1mm. This precision eliminates gaps, reduces noise, and ensures that internal components like motors and batteries perform reliably over time.

You might wonder why a toy needs such high precision. The answer is simple: vibration and water resistance. If the plastic parts do not fit together perfectly, the product will leak. If the motor is not held tightly, it will make a loud, annoying noise.

At our factory, we have 13 professional production lines. We use automation to ensure that every part is identical. Our precision standard is ±0.1mm. This is thinner than a piece of paper. This tight fit allows us to create products that are truly waterproof (IPX7).

This precision also applies to the internal components. We use high-quality motors with copper cores or brushless designs. We do not use cheap motors that feel rough. We test our motors for 100,000 cycles. They stay strong and quiet. We call this the "Strong Heart, Quiet Power" combination.

The battery is another critical part. We use high-density lithium batteries. We weld them precisely to the circuit board. We tested our batteries, and after 500 charging cycles, they still hold a strong charge. This is much better than the industry average. Precise manufacturing means your customer gets a product that lasts for years, not weeks. This saves you from handling warranty claims and refunds.

Why Is a Strict Quality Control System Your Best Insurance?

Defective products destroy customer trust12 and your reputation. You cannot check every single box yourself before it ships. You need a partner who acts as your eyes.

A comprehensive quality control system involves raw material testing, 100% finished product inspection, and vigorous performance testing13. Standards like ISO 285914 ensure that every shipped unit meets safety certifications and functions exactly as designed.

Quality control is not just checking the final product. It is a system that runs through the whole process. I treat your products as if they were my own. We are ISO 900115 certified, and we pass Sedex SMETA audits16. This means our system is internationally recognized.

Our process starts with the raw materials, as I mentioned before. But it goes much deeper. We perform "Full Inspection" and "Sampling Inspection."

- 100% Full Inspection: Every single unit is turned on and tested. We check the vibration patterns, the charging function, and the surface finish. We do not skip any unit.

- Strict Sampling: We use the ISO 285914 standard to pick random units for extreme testing.

We do drop tests to make sure the product does not break if it falls. We do temperature tests to ensure the battery is safe. We check the noise level to ensure it is below 55 decibels. We found that our low-frequency vibration improves stimulation by 45%. We only know this because we test it constantly.

We also have a smart four-layer protection system for our batteries. This prevents overheating and explosion risks. Safety is the number one priority for adult products. By doing these strict tests, we reduce your risk. You can sleep well knowing that the products arriving at your warehouse are safe and compliant with CE, FCC, and UKCA standards. We do the hard work so you do not have to worry.

Conclusion

Your brand needs a manufacturer who understands materials, design, precision, and quality control. By focusing on these details, you ensure safe, beautiful, and durable products that build customer loyalty.

References

Understanding the injection molding process is crucial for ensuring high-quality products and maintaining brand reputation. ↩

Exploring the advantages of premium materials can help you enhance product quality and customer satisfaction. ↩

Learn how optimizing mold design can prevent defects and save costs in production. ↩

Discover how minor design tweaks can lead to significant savings and improved product quality. ↩

Understanding parting lines can help you improve product aesthetics and functionality. ↩

Learn about the significance of gate locations in achieving a seamless product finish. ↩

Understanding food-grade Silicone can help you ensure product safety and quality. ↩

Learn about these regulations to protect your brand from legal risks and ensure compliance. ↩

Explore the specific challenges in the adult toy industry to better understand market demands and safety requirements. ↩

Discover why leftover materials can compromise product safety and quality, leading to potential legal issues and customer dissatisfaction. ↩

Explore the critical aspects of material selection to ensure safety and compliance. ↩

Learn strategies to enhance customer trust and loyalty through effective quality control measures. ↩

Explore the importance of performance testing to ensure product reliability and customer satisfaction. ↩

Understanding ISO 2859 helps ensure your products meet international quality standards, reducing defects and enhancing customer satisfaction. ↩

ISO 9001 certification ensures consistent quality management, boosting product reliability and customer trust, essential for maintaining brand reputation. ↩

Understanding Sedex SMETA audits helps ensure your manufacturer meets ethical standards, enhancing brand reputation and customer trust. ↩